I had a broken Samsung MM-N6 audio system and so I've decided to build myself a double sided UV exposure box using it's front panel since it already had an LCD display, buttons and a sliding motorized panel. The sliding panel can be replaced with a door.

Here is an overview video with the version 1 of the box. This article presents an improved version of this box.

Ultraviolet (UV) exposure box main key points:

The inside of the exposure box must be black. This is because you don't want the light to reflect from the sides and slip through the mask. Ideally the light must come only from the top and bottom. I have used black sticky vinyl but paint is another option.

The light must be uniform in intensity so that all parts of the board can have the same exposure. A light diffuser can be made out from tracing paper. More on this later.

With this setup the exposure time for presensitized boards is 8 minutes and with negative photoresist dry film exposure time is 25 seconds. PCB traces can be 0.3mm or even 0.2mm but for the 0.2mm the rate of success is lower.

Box dimensions and construction:

The UV exposure box is powered by a 12V, 2A power adapter.

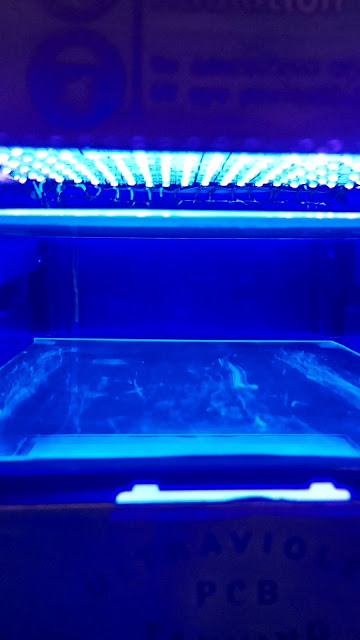

At the top there is a light used for aligning the mask made using a plastic sheet with tracing paper glued on the bottom. White paint would be better. The led strips are mounted about 3 cm below.

Light intensity can be adjusted using PWM.

In the middle there is a transparent plastic sheet on which the board to be exposed will be placed. 7 cm above is a wood sheet with ultraviolet LED strips on it and 2 or 3 cm below the leds is a plastic sheet with two pieces of tracing paper used to difuse the light so the individual leds can't be seen.

Detail with the ultraviolet led strips and the light diffuser beneath it. The same setup is copied for the bottom side with the exception that the leds are placed 5mm closer to the center plastic sheet. That is because the PCB is held tight by two pieces of plastic sheets that have some nuts at the bottom that is raising the board a bit. Also the bottom side diffuser has only one piece of tracing paper not two as above, the reason being the center plastic sheet that the light must pass through from the bottom but this is not the case for the light from the top. So the top diffuser has two sheets of paper to compensate for the middle plastic sheet.

Below you can see the leds used to align the top and bottom masks. After realizing it's way to much light, I have removed every other led strips.

|

| Way too many LEDs |

Each sheet can be slide in using grooves. The grooves are made gluing two pieces of wood with a space between them. The sheets of wood were also covered in black vinyl.

The inside is 18cm width by 20cm depth.

Electrical part:

Ultraviolet LED strip is a 5050 UV SMD LED strip with 60 leds/m powered by 12V.Wavelength: 395 - 405nm.

The width of a LED strip is 1cm so for 18cm wide panel 18 LED strips are needed with 20cm length which equals 360 cm or 3.6 m of tape needed. Multiply this by two for the other side. So two roles of 5m are more than enough.

Avoid staring at the UV light because that could damage the eyes and skin.

For controlling the LEDs I've used a relay for each side (top and bottom) because I like the clicking sound.

If you have any questions, leave them in the comment section below.

No comments:

Post a Comment